Food Inspection Experts

We help food and ingredient companies protect their brand and deliver trusted products to consumers.

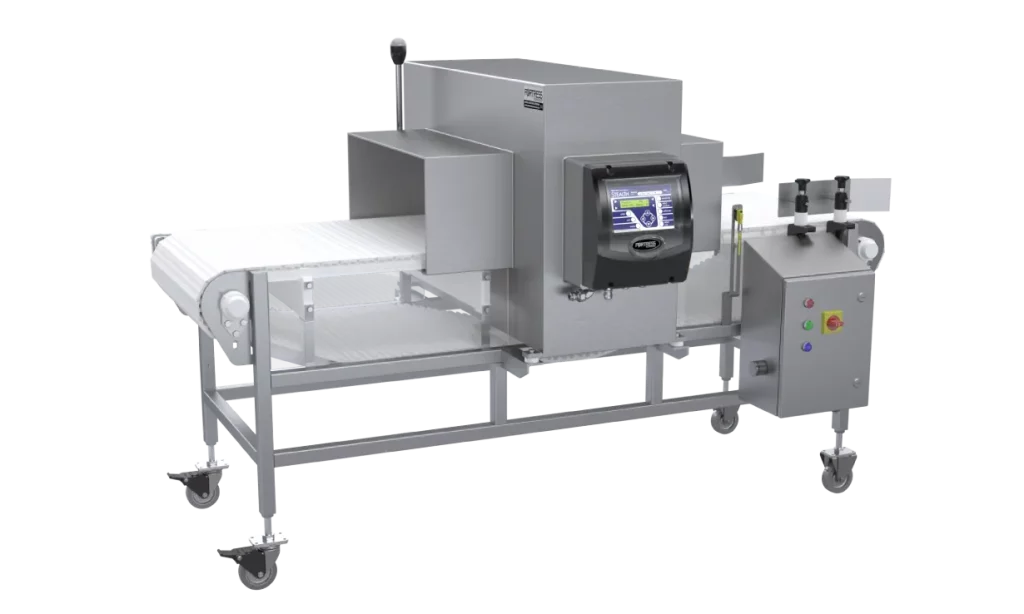

Metal Detectors

X-Ray Inspection

Checkweighers

About Wavesure

Founded in 2020, our company builds on 30+ years of combined experience of industry expertise to provide top-notch inspection solutions for the food processing and packaging sectors. As an official partner of Fortress Technology, Inc., we offer a range of advanced metal detection, checkweighing, and X-ray systems that set industry benchmarks.

Our team of dedicated professionals with deep industry expertise are committed to delivering the highest quality services and products to our clients

Our Services

Discover the initiatives Wavesure undertakes to support food safety and uplift communities in need.

Equipment Sales

Our sales approach is focused on understanding your process, risks, and production goals so you receive the right solution, not just a quote. We guide you through equipment selection, configuration, and implementation to ensure your investment delivers measurable value from day one.

Technical Support

Fast, knowledgeable technical support is at the core of Wavesure’s service philosophy. Our factory-trained technicians provide troubleshooting, maintenance, calibration, and on-site service to keep your inspection systems running at peak performance and minimize costly downtime.

Rental Solutions

Wavesure’s rental program offers flexible access to inspection systems without the upfront capital expense. Whether for temporary production needs, product trials, or compliance requirements, our ready-to-deploy rental units deliver dependable performance with full technical support included.

Spare Parts

We maintain a dedicated inventory of critical spare parts, both in our warehouse and stocked within our service vehicles, to ensure a rapid response when you need it most. Our approach helps extend equipment life, reduce downtime, and keep your production line moving with confidence.

Join the Food Safety Revolution

Take action today to ensure your business meets rigorous food safety requirements with our expert support and reliable equipment.

Industries We Serve

Produce

Nuts

Dairy

Dried Fruit

Baking

Nutraceutical

Meat

Rice

Grains

Confectionary

Snack Food

Poultry

Coffee

Beverage

Flour

Pharmaceutical

Years of working across a wide range of production environments have given us a deep understanding of how inspection systems behave in the real world: under moisture swings, varying product densities, fast line speeds, metalized packaging, and everything in between. This broad field experience means our team shows up already understanding the patterns, pitfalls, and opportunities others might miss, allowing us to deliver equipment and support that simply work.

Inspiring Transformation Stories

Real-life stories showcasing the impact of Wavesure’s commitment to food safety and client success.

Reliable Detection, immediate Results

A ground beef processor replaced unreliable metal detectors with Stealth systems from Fortress Technology to strengthen product safety and reduce risk. Soon after installation, the new systems began identifying a significant amount of small metal fragments that had previously gone undetected, allowing our customer to take corrective action, protect consumers, and restore confidence in their inspection process.

Preventing Costly Loss

A company discovered that an ingredient from a supplier was contaminated with small stones, putting finished product inventory at risk. Using Wavesure’s X-ray rental system, they were able to quickly inspect affected production, isolate compromised product, and release safe inventory, avoiding a costly loss while maintaining customer confidence and supply continuity.

Some Clients We Serve

Stay Compliant, Stay Secure

Join us in prioritizing food safety through reliable equipment and unparalleled technical service.

What Customers Say

FAQ

How do I know which inspection system is right for my product?

Different products behave differently in inspection; density, moisture, salt content, packaging type, and product temperature can all affect sensitivity. We help you choose the correct technology and configurations so you avoid false rejects and stay compliant.

What contaminants can an X-ray system detect that a metal detector can’t?

X-ray can identify dense materials like glass, mineral stones, bone, and some plastics in addition to metal. It’s often the best option when packaging is metalized or foil-based.

How accurate is a checkweigher?

Checkweigher accuracy depends on conveyor speed, product handling, and system design. For retail-sized packages accuracy can be within decimals of a gram. We help configure the right setup so you hit your weight targets consistently without slowing production.

Do metalized or foil packages require special equipment?

Yes. X-ray inspection is an excellent solution for metallized or foil packaging since the packaging material does not interfere with detection. In some applications, a metal detector can also be effectively installed upstream, such as between the bagger and the checkweigher, allowing final product inspection before packaging is applied.

How often should operators test the system?

Absolutely. Calibration, validation, and full performance testing are part of our standard service and included with every installation. QA teams tell us this removes a lot of stress during CCP verification.

How often should operators test the system?

Most facilities test at start-up, hourly, and at product changeovers depending on their HACCP plan. We train your team (English/Spanish) on correct testing procedures so results are consistent across shifts.

Can you integrate new systems with our existing conveyors or automation?

Yes. We regularly match detectors, X-ray units, and checkweighers to existing lines and help engineers verify proper spacing, reject mechanisms, and throughput.

Why do metal detectors give false rejects?

Most false rejects come from unstable product signals, radio frequency interference, isolation missing in the nearby hardware, vibration, or incorrect settings. Our techs perform root-cause diagnostics to stabilize performance and train your team to prevent repeat issues.

Contact Us

At Wavesure, we’re committed to helping food manufacturers ensure product safety and compliance with industry standards. Whether you need expert advice, need a system, or technical support, our team is here to help.

We prioritize fast response times and expert support to keep your production running smoothly. We look forward to connecting with you!